Sheet Metal Laser Cutting

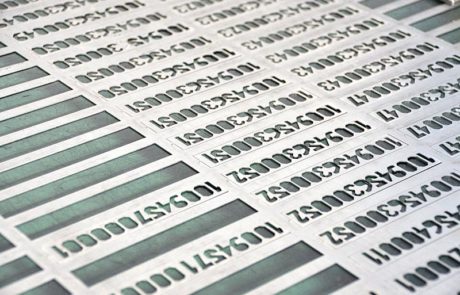

Laser is a high-tech process used for the thermal cutting of sheet metal.

Through the emission of a laser beam generated by a source applied to a Cartesian axis handling system, it is possible to obtain parts with the most varied shapes and sizes, starting from flat metal sheets

FLAMA has an optic fiber laser cutting system and a CO₂ laser cutting system thus guaranteeing the possibility to provide parts of any material and thickness, in small, medium and large series.

CO₂ laser cutting technology guarantees an excellent cutting finish and is adaptable to different types of materials and thicknesses, allowing us to be the ideal partner for every need.

The optic fiber laser cutting technology, thanks to very high cutting speeds, guarantees high production capacity and strong economic competitiveness, for the production of medium and large series.

In this way we can guarantee the processing of a wide range of thicknesses and materials, such as carbon steel, stainless steel, aluminum and non-ferrous metals (copper and brass).

Infinite Shapes and Infinite Ideas

Infinite shapes and dimensions, this is the aim of our modern laser cutting systems with which we can process materials such as carbon steel, stainless steel, aluminum and non-ferrous metals (copper and brass) to serve the most varied industrial sectors and meet every need.

What materials do we process?

Carbon steel, stainless steel, aluminum and non-ferrous metals (copper and brass).

Flexibility and Versatility

An integrated CAD/CAM system ensures a simple transfer of information from the design phase through to the production phase.

In this way, the machines are programmed quickly and flexibly, ensuring that modifications and sampling can be carried out at reduced costs.

Continuous and Automated Production Cycles

Our cutting plants are automatically fed through a vertical warehouse from which the raw material is taken, allowing continuous and optimized production cycles, in this case also the unloading and palletizing of the processed components is fully automatic.

Our machine fleet

CONTACT US

Flama Srl

Via Martiri di Cefalonia e Corfù, 15

37014, Castelnuovo del Garda (Verona)

(+39) 045 6450917

segreteria@flama.it

Commercial: commerciale@flama.it

Data protection officer: dpo-rdp@flama.it